September 29th, 2025

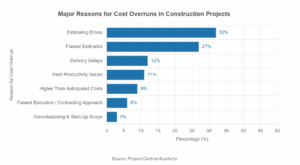

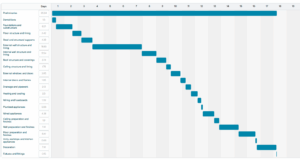

For architects, contractors, and developers, the cost of a home extension in London depends on a host of factors, including specification, contractor size, design complexity, and other project-specific considerations.

This guide outlines the key cost drivers you should discuss with clients, helping them understand not just the price, but also the impact of design choices on outcomes.

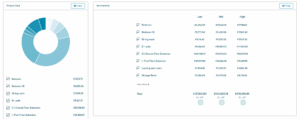

We’ve included a detailed breakdown by project elements to show the percentage of things like drainage, appliances, wiring to give clear picture of where budgets are allocated and where potential savings or upgrades can be considered.

Extension Cost Calculations

In our cost calculations, the following specifications have been assumed for all extensions:

- The roof of the extension is pitched, rather than flat.

- The structure is built using brick and block construction, rather than a timber frame.

The extensions considered in these calculations include the following room configurations:

- 20m² single-storey rear extension: comprising a dining room, utility room, and WC.

- 20m² shell plus 40m² gross internal floor area (GIFA) wrap-around extension with ground-floor remodel: including a dining room, utility room, and WC.

- 40m² double-storey rear extension: including a dining room, utility room, WC, an additional bedroom with en-suite bathroom, a storage room, and a small landing.

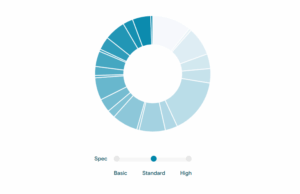

In terms of build specification, BuildPartner gives you three broad options to choose from:

- Basic spec is a basic finish; e.g., Leyland, Everest, Wickes.

- Standard spec is a standard finish; e.g., Dulux, Hamilton, Slim Line.

- Premium spec is a high-spec finish; e.g., Farrow & Ball, Fine Line, Siemens.

In this article, we’ve provided a breakdown of the cost of building an extension to all three specifications. In addition, we have provided three different benchmarks to show the range of pricing you can expect among different contractors. These are:

- Low benchmark – smaller companies are generally lower cost but less specialised and with low project management function; good for low/mid-spec projects and tight budgets.

- Mid benchmark – medium-sized companies offer a balanced mix of cost-effectiveness and specialisation; good for mid-range projects for effective execution within moderate budgets.

- High benchmark – larger companies generally have a higher cost base but can handle a wide variety of specialist tasks; good for mid/high-spec projects and project management.

The specification and benchmark you choose will have a major impact on the overall cost of building an extension, so it’s important to align them with your budget and the level of finish you’re aiming for.

Cost Of Building A Single-Storey Rear Extension In London

The table below shows the average cost of building a single-storey extension in London (20m2):

| Single-Storey Rear Extension | Total Average Build Cost | ||

| Low Benchmark | Mid Benchmark | High Benchmark | |

| Basic Spec | £66,007 | £73,808 | £81,008 |

| Standard Spec | £70,430 | £78,754 | £86,437 |

| Premium Spec | £79,513 | £88,910 | £97,584 |

| Average | £71,983 | £80,491 | £88,343 |

The table below shows the average cost per square metre of building a single-storey extension in London (20m2):

| Single-Storey Rear Extension | Average Cost Per Sq Metre | ||

| Low Benchmark | Mid Benchmark | High Benchmark | |

| Basic Spec | £3,300 | £3,690 | £4,050 |

| Standard Spec | £3,522 | £3,938 | £4,322 |

| Premium Spec | £3,976 | £4,446 | £4,879 |

| Average | £3,599 | £4,025 | £4,417 |

All costs exclude VAT.

Here’s what the data shows for building a single-storey extension in London:

- The minimum cost is £66,007, and the maximum cost is £97,584.

- The total average cost is £80,491, or £4,025 per square metre.

Start your free trial with BuildPartner to get a bespoke estimate of your construction project within minutes.

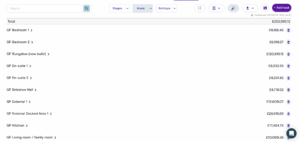

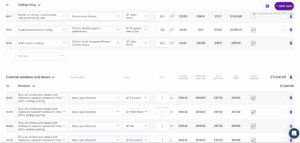

Cost By Stages For Single-Storey Extension In London

The table below shows the average cost by project stage for a single-storey extension in London (20m2):

| Total | £78,754 | 100% |

| Preliminaries | £12,005 | 15.2% |

| Foundations and substructure | £9,302 | 11.8% |

| External wall structure and lining | £8,395 | 10.7% |

| Roof structure and coverings | £8,145 | 10.3% |

| Steel and structural supports | £4,916 | 6.2% |

| Decoration | £4,371 | 5.5% |

| Floor preparation and finishes | £4,239 | 5.4% |

| Units, worktops and kitchen appliances | £4,180 | 5.3% |

| External windows and doors | £4,092 | 5.2% |

| Wired appliances | £2,881 | 3.7% |

| Floor structure and lining | £2,526 | 3.2% |

| Drainage and pipework | £2,290 | 2.9% |

| Internal wall structure and lining | £2,123 | 2.7% |

| Heating and cooling | £1,891 | 2.4% |

| Wall preparation and finishes | £1,824 | 2.3% |

| Internal doors and frames | £1,369 | 1.7% |

| Plumbed appliances | £1,270 | 1.6% |

| Demolitions | £1,208 | 1.5% |

| Wiring and fuseboards | £546 | 0.7% |

| Fixtures and fittings | £427 | 0.5% |

| Ceiling structure and lining | £387 | 0.5% |

| Ceiling preparation and finishes | £367 | 0.5% |

Cost Of Building A Ground-Floor Wrap-Around Extension In London

The table below shows the average cost of building a wrap-around extension and remodelling the ground-floor plan (20m² extension shell plus 40m² of gross internal floor area):

| Ground-Floor Wrap-Around Extension & Remodel | Total Average Build Cost | ||

| Low Benchmark | Mid Benchmark | High Benchmark | |

| Basic Spec | £86,165 | £97,772 | £100,287 |

| Standard Spec | £98,105 | £111,062 | £113,696 |

| Premium Spec | £120,561 | £136,056 | £138,550 |

| Average | £101,611 | £114,963 | £117,511 |

The table below shows the average cost per square metre of building a wrap-around extension and remodelling the ground-floor plan (20m² extension shell plus 40m² of gross internal floor area):

| Ground-Floor Wrap-Around Extension & Remodel | Average Cost Per Sq Metre | ||

| Low Benchmark | Mid Benchmark | High Benchmark | |

| Basic Spec | £2,154 | £2,444 | £2,507 |

| Standard Spec | £2,453 | £2,777 | £2,842 |

| Premium Spec | £3,014 | £3,401 | £3,464 |

| Average | £2,540 | £2,874 | £2,938 |

All costs exclude VAT.

Here’s what the data shows for the cost of building a wrap-around extension and remodelling the floor plan:

- The minimum cost is £86,165, and the maximum cost is £138,511.

- The total average cost is £114,963, or £2,874 per square metre.

Cost Of Building A Double-Storey Extension In London

The table below shows the average cost of building a double-storey extension in London (40m2):

| Double-Storey Side Extension | Total Average Build Cost | ||

| Low Benchmark | Mid Benchmark | High Benchmark | |

| Basic Spec | £117,257 | £133,166 | £136,417 |

| Standard Spec | £131,478 | £148,994 | £152,139 |

| Premium Spec | £156,600 | £176,956 | £180,102 |

| Average | £135,112 | £153,039 | £156,219 |

The table below shows the average cost of building a double-storey extension per square metre in London (40m2):

| Double-Storey Side Extension | Average Cost Per Sq Metre | ||

| Low Benchmark | Mid Benchmark | High Benchmark | |

| Basic Spec | £2,931 | £3,329 | £3,410 |

| Standard Spec | £3,287 | £3,725 | £3,803 |

| Premium Spec | £3,915 | £4,424 | £4,503 |

| Average | £3,378 | £3,826 | £3,905 |

All costs exclude VAT.

Here’s what the data shows for the cost of building a double-storey extension (40m2) in London:

- The minimum cost is £117,257, and the maximum cost is £180,102.

- The total average cost is £153,039, or £3,826 per square metre.

Average Cost Of Building An Extension In London

So, how much does it cost to build an extension in London? Based on the three types of builds covered in this article, it costs on average:

- Single-Storey Rear Extension: £80,491, or £4,025 per square metre.

- Ground-Floor Wrap-Around Extension & Remodel: £114,963, or £2,874 per square metre.

- Double-Storey Side Extension: £153,039, or £3,826 per square metre.

It’s also worth noting that your final cost could be lower or higher depending on the quality of materials you choose.

Start your free trial with BuildPartner to get a bespoke estimate of your construction project within minutes.

Please remember that all costs exclude VAT.

Frequently Asked Questions About Building Extensions In London

Here are some answers to frequently asked questions about building extensions in London.

What are the challenges of building an extension on a Victorian terrace with no side access?

Building an extension on a Victorian terraced house with no side access is perfectly achievable, but it presents some logistical challenges. Without an external route to the rear, all materials, tools, and waste must be carried through the house.

With limited space for storage or skips, contractors may need street permits or timed deliveries, while strict London noise regulations can further slow the pace of work.

Are there restrictions on building work hours in London?

Most London boroughs limit noisy construction work to 8am to 6pm on weekdays and 8am to 1pm on Saturdays, with no loud work permitted on Sundays or bank holidays.

These hours are similar to those across most of the UK, but enforcement in London is usually tighter because homes are closer together and noise complaints are more common.

Are side return extensions suitable for terraced Victorian houses?

Yes, they’re very popular in London terraces. A side return extension fills the narrow space beside a kitchen or living area, creating extra usable space without extending too far into the garden. Rooflights or glass ceilings are often needed to ensure adjoining rooms get enough natural light.

Are basement extensions still allowed in London?

They are, but they’re heavily regulated due to flooding and structural risks. Boroughs like Kensington and Chelsea, Camden, and Westminster have strict basement policies limiting depth (around 3 to 4 metres below ground level).

Developers usually need to submit detailed geological and structural surveys, plus a construction management plan showing how excavation, shoring, and water management will be handled.

Do I need to inform Thames Water before building?

If there’s a public sewer within 3 metres of your extension, you’ll need a Build-Over Agreement to ensure your construction won’t damage the sewer or block access for maintenance.

In London, where many Victorian and terraced homes connect to older public sewers, obtaining this agreement is quite common and should be factored into your planning process.

You can check if a property is near a public sewer by contacting Thames Water or carrying out an asset location search on their website.