Feasibility Study vs Detailed Schedule Of Costs: What’s The Difference?

When planning a project, there’s often a moment where you need to pause and ask: do we need a feasibility study, or are we ready to produce a detailed schedule of costs? They serve very different purposes, yet they’re often confused (and sometimes skipped altogether).

A feasibility study helps you determine whether a project is financially, operationally, technically, and legally viable before committing too much time or money. Whereas, a detailed schedule of costs is a thorough, itemised breakdown of exactly what the project will cost.

In this article, we’ll break down the differences between the two services, explore when each is appropriate, and explain how they both support better decision-making.

Start your free trial with BuildPartner to get a bespoke estimate of your construction project within minutes.

What Is A Feasibility Study?

Ultimately, a feasibility study is an early-stage assessment that determines whether a proposed project is viable. It helps avoid costly mistakes by testing assumptions before major commitments are made.

Typical areas covered include:

- Site constraints (planning, environmental, access)

- Approximate calculations of quantities and materials

- Design options and scope outlines

- Stakeholder needs and risks

- Regulatory and planning considerations

Feasibility studies provide broad-brushstroke cost estimates to guide initial project decisions.

They tell you whether to proceed with a project or go back to the drawing board to overcome any obstacles. For instance, the inclusion of additional bathrooms or underfloor heating might push the project over budget, prompting a rethink around necessities versus nice-to-haves.

A BuildPartner feasibility study includes approximate quantity calculations of each stage and area of a project, standard materials and finishes, and local market pricing. It’s carried out by a qualified, insured scheduler.

All projects can benefit from a feasibility study. Why invest in a detailed schedule upfront when a feasibility study can provide a reliable reality check on budget for a fraction of the cost?

This helps avoid unnecessary costs and supports informed decisions early on.

When Do You Need A Feasibility Study?

A feasibility study is most valuable at the very start of a project, often even before any drawings are produced, and certainly before significant design work, planning submissions, or funding applications take place.

You might consider a feasibility study if:

- The site, scope, or budget is still unclear

- You’re comparing project options or land uses

- External factors (e.g., planning, utilities, access) might derail the project

- You need to test viability before seeking funding or client sign-off

A feasibility study is often created at RIBA Stage 2 or 3 of a construction project (see FAQs for more info), but they can also be done at Stage 0 and 1. It helps stakeholders say no early or move forward with more clarity.

Need a feasibility study? We can provide expert support and collaborate with architects to deliver detailed drawings too.

Contact us at estimating@buildpartner.com

What Is A Detailed Schedule Of Costs?

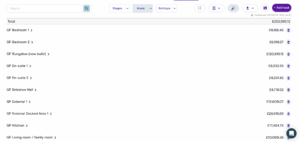

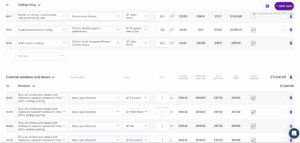

A detailed schedule of costs is a comprehensive, itemised breakdown of what a project will cost, based on an agreed design and scope.

It includes:

- Line-by-line breakdown of materials and labour

- Subcontractor and supplier pricing

- Project timeline of each project stage

Unlike feasibility estimates, these are based on real figures and design intent. And accuracy matters; even a minor error or omission can lead to major cost overrun, such as the misplacement of a decimal point and ordering 120m² of tiles instead of 12m².

A BuildPartner schedule of costs involves a detailed calculation of quantities, application of local market prices, and thorough research and inclusion of specified materials and their costs.

How does that compare with a feasibility study?

Well, a feasibility study might estimate patio doors for a 3m-wide opening, including materials and labour, at £3,200. While a detailed schedule of costs might detail specific bifold patio doors with integrated blinds, totalling £5,500.

In short, the feasibility study provides a broad estimate for early planning; the schedule of costs delivers an exact financial plan for construction.

Both services are carried out by qualified, insured schedulers at BuildPartner.

If you need a feasibility study or a specified cost schedule, please contact us at estimating@buildpartner.com

When Do You Need A Detailed Schedule Of Costs?

A detailed schedule of costs is usually prepared after technical drawings are completed, as these provide the detailed information needed for accurate cost quantification.

A detailed cost schedule is needed when:

- The design is developed enough to quantify accurately

- You’re preparing for a tender or engaging with contractors

- A lender, investor, or funding body needs transparent cost data

The schedule of costs is often created at RIBA Stage 4 of a construction project (see FAQs for more info), after the technical design. From then on in, it becomes a financial control tool, not just a pricing exercise.

For large projects, cost schedules may be created and revised throughout, especially at the tender stage, contract signing, and post-tender negotiations.

Key Differences At A Glance

The table below highlights the main differences between a feasibility study and a detailed schedule of costs:

| Aspect | Feasibility Study | Detailed Schedule of Costs |

| Purpose | Early-stage cost planning and viability testing | Detailed cost planning and accurate quoting |

| Timing | Pre-design or concept stage | Post-design, when scope is fixed |

| Detail Level | Approximate quantities; standard materials | Detailed quantities; specified materials and finishes |

| Materials & Finishes | Standard materials and finishes applied | Researched and populated with specified products and suppliers |

| Pricing Basis | Local market prices with standard rates | Bespoke rates, local prices, and detailed supplier quotes |

| Use Case | Exploring feasibility, securing early buy-in | Accurate pricing for contracting, tender, or funding |

| Prepared By | Qualified and insured BuildPartner scheduler | Qualified and insured BuildPartner scheduler |

| Cost

(BuildPartner) |

0.1% of project value (e.g., £200 on £200k project) Minimum charge: £150 | Qualified and insured BuildPartner scheduler

0.2% of project value (e.g., £400 on £200k project) Minimum charge: £300 |

How They Complement Each Other

Despite the comparison in the table above, feasibility studies and detailed cost schedules aren’t competing services. They’re part of the same planning journey. Think of it like this:

- Feasibility studies explore what’s possible.

- Specified schedules define the actual costs.

In essence, a feasibility study is part of an iterative approach to pricing. At the outset, you get a rough cost based on the project scope and surface area. Then, if it’s within budget, you can carry out a specified schedule to home in on cost and accuracy.

So the two aren’t mutually exclusive services.

If you skip the feasibility study, you risk implementing impractical designs; and if you rush into a cost schedule without agreeing on a defined scope, you can expect to see wild revisions at a later stage.

Starting this process earlier minimises potential waste on architectural costs.

Choosing the Right Service For The Stage You’re In

Selecting between a feasibility study and a detailed schedule of costs all boils down to timing. If your project is still in its early stages, with variables like site conditions, planning risk, or design scope not yet fixed, you probably need a feasibility study before committing.

Once the scope is clear and design decisions are locked in, a detailed cost schedule will provide you with a detailed breakdown needed for accurate quoting.

If you need a feasibility study or a specified cost schedule, please contact us at estimating@buildpartner.com. We also collaborate with architects to deliver detailed drawings too.

Frequently Asked Questions About Feasibility Studies & Cost Schedules

Here are some answers to frequently asked questions about feasibility studies and cost schedules in construction projects.

How accurate are feasibility studies compared to full-cost schedules?

Feasibility studies are indicative. They might be within 10 to 20% of final costs, or even greater if the project scope changes drastically.

Detailed schedules aim for much greater accuracy, often within 5 to 10%, providing no unexpected issues arise, such as unforeseen site conditions or design changes.

Do feasibility studies include detailed material specs?

Feasibility studies tend to use standard assumptions and typical finishes. Specific material choices and supplier pricing are included later in the detailed schedule.

At the feasibility stage, the goal is to check if the project makes sense without sweating the small stuff like picking Dulux over Crown paint or choosing specific types of fixtures. It’s about obtaining ballpark figures, not nailing down exact brands or suppliers.

Who typically carries out feasibility studies and cost schedules?

Feasibility studies can be undertaken by architects, planners, or cost consultants like BuildPartner. Detailed cost schedules are usually prepared by a quantity surveyor or specialist consultants. Working with experienced, insured professionals ensures the figures stand up to scrutiny.

Why is it important to have a qualified and insured scheduler?

A qualified scheduler ensures your cost plan is based on accurate quantities and a professional understanding of construction methods and pricing.

Being insured adds a layer of protection; if there’s a significant error or omission, there is clear path to addressing disputes and legal challenges.

Can I skip the feasibility study and go straight to a cost schedule?

Only if the project scope, site, and design are fully defined, otherwise you risk pricing the wrong thing or hitting roadblocks later.

Skipping the feasibility study can lead to false confidence in costings and timeframes. Doing so ultimately risks the possibility of incurring expensive revisions down the line.

What is the RIBA Plan of Work?

The RIBA Plan of Work 2020 was developed by the Royal Institute of British Architects, and it provides a structured framework for managing architectural and construction projects in the UK. The framework organises building projects into eight stages:

- Stage 0: Strategic Definition – Define objectives, business case, and feasibility.

- Stage 1: Preparation and Briefing – Develop project brief, budget, and site appraisals.

- Stage 2: Concept Design – Create initial designs and preliminary cost estimates.

- Stage 3: Spatial Coordination – Refine design, develop specifications, and planning.

- Stage 4: Technical Design – Finalise detailed designs and tender documents.

- Stage 5: Manufacturing and Construction – Oversee construction and manage progress.

- Stage 6: Handover – Complete construction, hand over the building, and address defects.

- Stage 7: Use – Monitor performance and conduct post-occupancy evaluations.

A feasibility study is usually carried out at Stage 2 or 3, but it’s not unusual to carry one out sooner at Stage 0 or 1. A detailed cost schedule is typically developed after the technical design at Stage 4.